Sculpture Fabrication 101: Working with Large Aluminium Pieces

25 February 2025

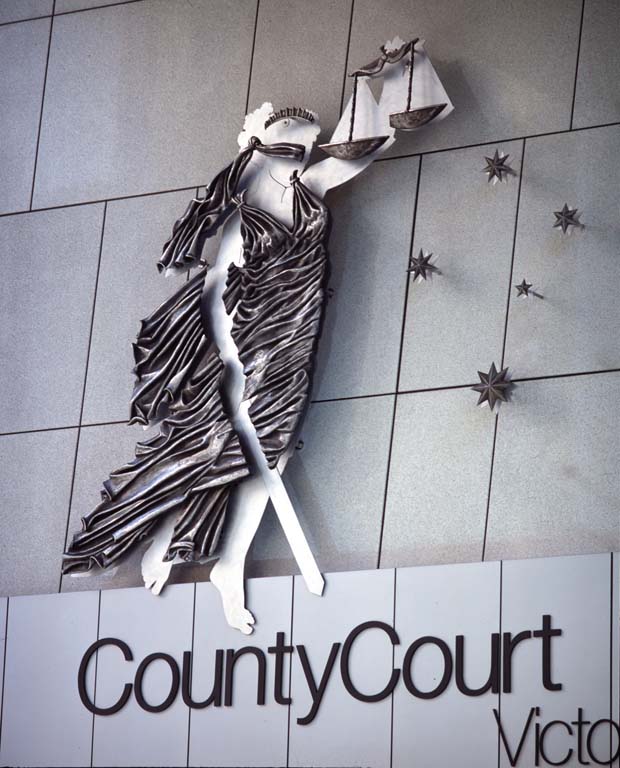

J K Fasham delivers high-quality sculpture fabrication with large aluminium pieces, offering unmatched craftsmanship for lasting artistic creations.

Sculpture fabrication demands precision and innovation, particularly when working with large aluminium pieces. This process transforms raw metal into intricate designs, providing sculptors with the flexibility to create durable and visually striking structures. This craftsmanship has been instrumental in the art and architectural industries for decades, demonstrating its importance in the realisation of creative visions.

Mastering Aluminium Fabrication for Large-Scale Sculptures

Aluminium is an ideal material for large-scale sculptures due to its durability, versatility, and lightweight nature, allowing for expansive yet manageable designs. Its malleability enables intricate detailing while maintaining structural integrity. Resistant to corrosion, it suits outdoor installations, ensuring longevity. With a sleek metallic finish and compatibility with various surface treatments, aluminium adapts to diverse artistic visions, making it a preferred choice for impactful, enduring artworks.

Surface Treatments in Aluminium Sculpture Fabrication

Surface treatments enhance aluminium sculptures by improving their aesthetic appeal and structural resilience, ensuring lasting performance in diverse settings. Each technique is carefully selected to align with the artistic vision and functional requirements of the project.

The following are ten surface treatments for aluminium sculptures, each offering unique benefits to enhance both their appearance and longevity.

1. Polishing: Produces a high-gloss, reflective surface that enhances the metallic elegance of aluminium and creates a modern, sophisticated aesthetic.

2. Brushing: This creates a uniform, matte texture with fine parallel lines that reduce glare while adding a subtle industrial charm.

3. Anodising: Enhances corrosion resistance and colour options by forming a protective oxide layer that can be dyed in vibrant or natural tones.

4. Sandblasting: Provides a matte, textured finish that adds depth and character while increasing surface adhesion for additional treatments.

5. Powder Coating: Applies a durable, decorative layer available in various colours and textures, offering enhanced protection against environmental damage.

6. Etching: Engraves intricate patterns or designs onto the surface, allowing for custom detailing that adds uniqueness to the sculpture.

7. Clear Coating: Preserves the natural look of aluminium with a transparent protective layer that shields it from oxidation and fading.

8. Chemical Patination: Creates a range of aged or artistic effects by chemically reacting with the surface, adding colour and texture variations.

9. Painting: Applies vibrant or muted colours with a smooth or textured finish, allowing for complete creative control over the sculpture’s appearance.

10. Oxidising Treatments: Deliberately accelerates oxidation to produce rich, earthy hues and textures, achieving an organic, weathered aesthetic.

Partnering with sculptors, JK Fasham crafts stunning aluminium sculptures that stand the test of time. As a reputable family-owned architectural metal fabrication company, it brings a wealth of experience and precision to each project, ensuring artists’ conceptions are realised with unparalleled quality. Refine your large aluminium sculptures with our tailored surface treatments, ensuring both stunning aesthetics and long-term resilience.

For more information on Aluminium Material Properties: https://www.ga.gov.au/education/minerals-energy/australian-mineral-facts/aluminium

Other related blog: Custom Large-Scale Sculpture Fabrication: Cutting-Edge Techniques for Monumental Arts

Optimized by: Netwizard SEO