The Role of Quality Control in Precision Sculpture Fabrication in Melbourne

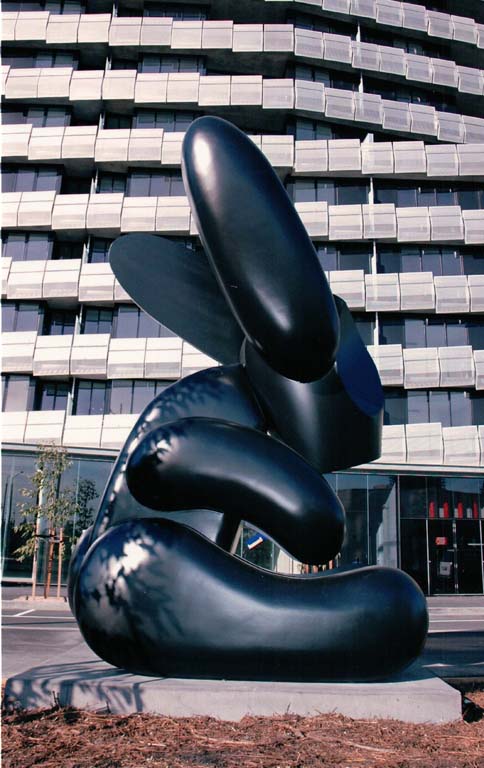

19 February 2026 Ensure public art longevity with expert sculpture fabrication in Melbourne. JK Fasham provides QC and compliance for durable, high-quality results.

Ensure public art longevity with expert sculpture fabrication in Melbourne. JK Fasham provides QC and compliance for durable, high-quality results.

When commissioning public art, the transition from a maquette to a full-scale installation requires more than just skilled labour; it requires a rigorous framework of quality standards. At JK Fasham, our sculpture fabrication in Melbourne ensures that complex artworks are not only visually stunning but also structurally compliant and built to last.

Why Quality Control is the Foundation of Artistry

For any significant project involving artwork fabrication, quality control (QC) serves as the measurable benchmark. It ensures the final output aligns perfectly with the artist’s approved drawings and engineering specifications.

By implementing disciplined inspection processes at every production stage, we achieve a level of fabrication accuracy that protects the artistic intent while satisfying local council and safety regulations.

5 Critical Quality Checkpoints in the Fabrication Process

To maintain structural integrity and visual consistency, we utilise defined quality checkpoints throughout the project lifecycle.

| Stage | Technical Focus | SEO/Compliance Value |

| 1. Material Verification | Grade & thickness assessment | Ensures suitability for metal sculpture fabrication. |

| 2. Dimensional Validation | Tolerance & alignment checks | Minimises deviations in complex geometric sequences. |

| 3. Weld Integrity | AS/NZS 5131 & ISO 3834 | Guarantees safety and load-bearing performance. |

| 4. Surface Preparation | Substrate assessment | Vital for the longevity of protective coating systems. |

| 5. Pre-Assembly | Trial fitting | Verifies fit and balance before on-site sculpture installation. |

Engineering for Long-Term Durability

Quality assurance extends beyond the workshop floor. To prevent the need for premature sculpture restoration, we integrate high-level engineering into the fabrication phase:

• Structural Load Verification: We use engineering computations to confirm sculptures can withstand specific wind loads and environmental stresses.

• Protective Coating Systems: Industrial-grade coatings are selected to resist UV exposure and corrosion.

• Logistics & Relocation: Our QC process includes planning for safe sculpture relocation and transport stability.

Dependable Artwork Fabrication Outcomes

High-quality fabrication succeeds when the technical process protects the creative vision. JK Fasham provides the infrastructure and expertise to bring monumental art to life through proven sculpture fabrication materials and certified workflows.

Ready to discuss the technical requirements of your next project? Contact us at JK Fasham today to ensure a compliant and durable result.

Related Blog Articles:

How Engineering Computations Shape Sculpture Design

Sculpture Fabrication Materials Explained: Stainless Steel, Aluminium, and Bronze

Sculpture Installation: Why Concrete Footings are Essential

Sculpture Restoration: The Art of Saving Stainless Masterpieces

Optimized by: Netwizard SEO